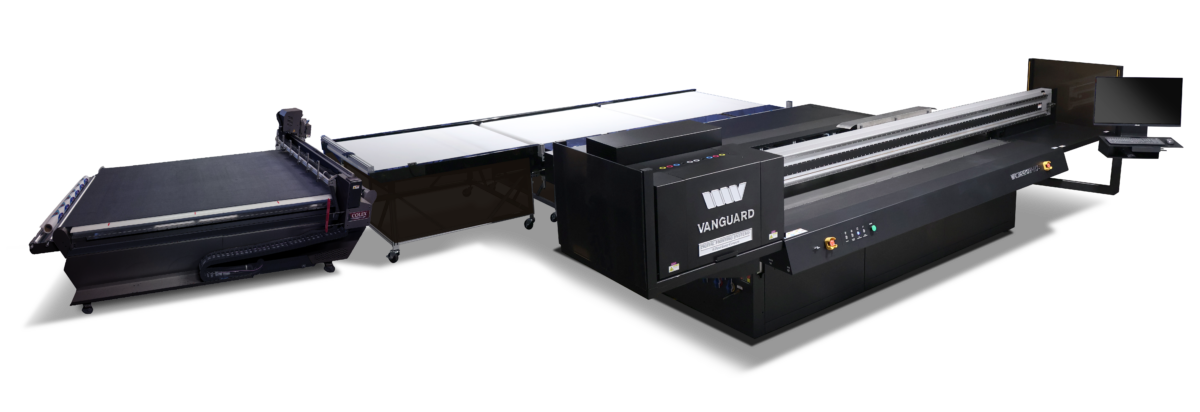

HARPETH PRINT-TO-CUT

WORKFLOW SOLUTION

VANGUARD ULTRA-HIGH PRODUCTION

FLATBED UV-LED PRINTER & COLEX SHARPCUT CUTTER

One way to maximize a printer’s throughput potential is to automate media handling. Vanguard Digital and Colex have collaborated to provide a fully automated print-to-cut workflow to simplify rigid print production for the Sign & Display and Packaging market to reduce turnaround time for clients and brands.

The Harpeth automated print-to-cut system is comprised of the VK3220T-HS UV-LED flatbed printer from Vanguard, and the in-line transport system partnered with the Vanguard edition of the Sharpcut digital cutter from Colex. With the ability to automate the workflow between print and cutting, Print Service Providers can reduce cost and reduce media handling times for greater productivity. In today’s competitive landscape, efficiency is the key to success in any print business, as well as with clients and brands.

HARPETH = VK3220T-HS FLATBED + SHARPCUT CUTTER

THE MIGHTY VK3220T-HS FROM VANGUARD

THE VANGUARD EDITION COLEX SHARPCUT

With a larger bed size and up to three rows of printheads, the VK3220T-HS UV-LED flatbed from Vanguard redefines production potential for Print Service Providers. Throughput potential is maximized when handling time is nearly eliminated with the Harpeth solution.

The VK3220T-HS comes combines Kyocera KJ4A printheads that deliver print dots as small as 4pl, along with an electromagnetic drive ensuring tight dot placement for remarkable print quality and remarkable speeds. The 3.2 x 2 meter (126” x 80”) bed size of the VK3220T-HS furthers throughput potential.

For peace of mind, the VK3220T-HS is engineered to grow with your business; channels can be added after installation, providing the flexibility needed to respond to business demands. Optional white ink and varnish expand application potential, and with the ability to print on nearly any substrate up to 4″ (10cm) thick, the only limitation is your imagination!

The Colex Sharpcut Digital Flatbed Cutter complete turnkey solution will help automate print service providers’ workflows and reduce costs associated with the finishing process of large format goods.

The Colex Sharpcut is an easy-to-use cutting solution with an intuitive software platform at its core. Though competitively positioned, it is not to be underestimated for its versatility, throughput, and its ability to help you unlock the full potential of the VK3220T-HS flatbed printer. This can open the doors to new opportunities, reduce costs, and help increase production while tapping into new revenue streams.

The Colex Sharpcut Finishing System features an automated and easy-to-use workflow solution for nesting and optimizing media. And to make the cutter even more productive, the Sharpcut Conveyor efficiently speeds up the removal of finished jobs from the cutting table.

VANGUARD

CUTTING EDGE TECHNOLOGY

van·guard /ˈvanˌɡärd/

a group of people leading the way in new developments or ideas.

ALIGNGUARD

Air assisted pin registration provides precise media alignment with every print.

PRESSUREGUARD

Provides stability within the negative pressure system which increases the life cycle of critical components.

CUREGUARD

Precisely adjustable LED curing technology allows you to print to more substrates with greater control.

ACCUGUARD

A metal raster strip provides the most accurate dot placement in the industry.

PRINTGUARD

Reduce time and waste with pinpoint accurate print resuming after a crash sensor has been reset.

NOISEGUARD

Twin mufflers reduce the noise level of the powerful media vacuum pumps.

BANDGUARD

Virtually eliminate chromatic banding, allowing you to print at faster speeds and better quality.

TIMEGUARD

Increase productivity and reduce labor by accurately printing from front to back and back to front.

MEDIAGUARD

Measure media thickness with our auto-height detection system in just a matter of seconds.

STATICGUARD

Be proactive by reducing static charges on acrylics and other positively charged substrates.

***All Vanguard Digital printers are CE certified and can be CSA certified upon request.

AWARD WINNING WIDE FORMAT PRINTERS

Winner of Numerous SGIA Product of the Year & Printing United Alliance Pinnacle Product Awards

For eight years in a row, Vanguard Digital has been honored with the PRINTING United Alliance’s prestigious Pinnacle Product Award (formerly the Specialty Graphic Imaging Association’s [SGIA] Product of the Year award) in a number of printer categories. This annual competition showcases the highest quality machines and most innovative advancement in the specialty imaging and print industry.