HARPETH HIGH-PRODUCTION WORKFLOW SOLUTION

VANGUARD ULTRA-HIGH PRODUCTION FLATBED UV-LED PRINTER & AUTOMATION SYSTEMS

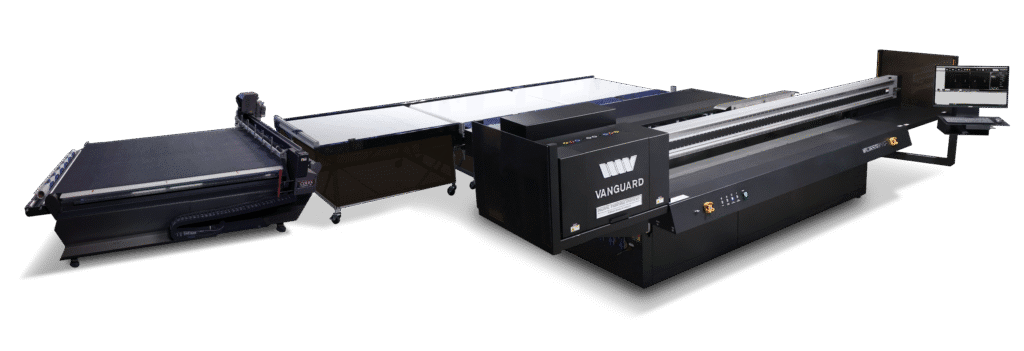

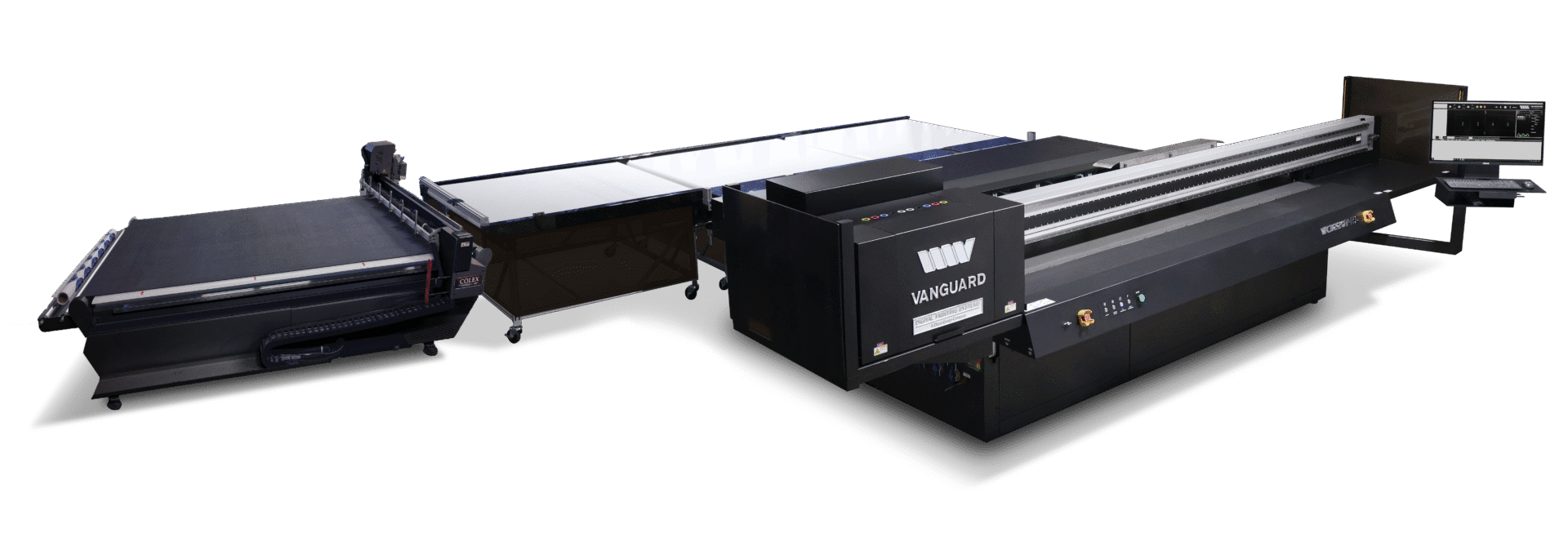

One way to maximize a printer’s throughput potential is to automate media handling. Vanguard Digital and Colex have collaborated to provide a fully automated print-to-cut workflow to simplify rigid print production for the Sign & Display and Packaging market to reduce turnaround time for clients and brands. The Harpeth automated print-to-cut system is comprised of the VK3220T-HS UV-LED flatbed printer from Vanguard, and the in-line transport system partnered with the Vanguard edition of the Sharpcut digital cutter from Colex. With the ability to automate the workflow between print and cutting, Print Service Providers can reduce cost and reduce media handling times for greater productivity. In today’s competitive landscape, efficiency is the key to success in any print business, as well as with clients and brands.

MEET THE

HARPETH FROM VANGUARD

One way to maximize a printer’s throughput potential is to automate media handling. Vanguard Digital created the modular Harpeth system to simplify rigid print production for the Sign & Display and Packaging market to reduce turnaround time for clients and brands. With the choice of Harpeth Print-To-Cut, or Harpeth Print-To-Stack, automation is at the tip of your fingers.

This dynamic and flexible printing solution recognizes the needs of today’s print service providers, and empowers users to combine a powerful printer, and a workflow solution that meets their needs. The Harpeth redefines productivity and elevates your print shop, making you more competitive in today’s fast paced market.

The Harpeth comes combines Kyocera KJ4A printheads that deliver print dots as small as 4pl, along with an electromagnetic drive ensuring tight dot placement for remarkable print quality and remarkable speeds. The 3.2 x 2 meter (126” x 80”) bed size of the VK3220T-HS furthers throughput potential.

For peace of mind, the Harpeth is engineered to grow with your business; channels can be added after installation, providing the flexibility needed to respond to business demands. Optional white ink and varnish expand application potential, and with the ability to print on nearly any substrate up to 4″ (10cm) thick, the only limitation is your imagination!

Request a Brochure

Product Brochure

"*" indicates required fields

DOWNLOAD THE HARPETH INFO SHEET

HARPETH Product Brochure

"*" indicates required fields

THE VANGUARD

VK3220T-HS

• CMYK + optional White + optional Varnish for expanded application potential

• Variable drop technology and 4 picoliter drop sizes for better color gradients and smoothing capability

• Magnetic linear drive control for accurate dot placement at ultra-high speeds

• High-volume ink jetting at an accurate level to support productivity

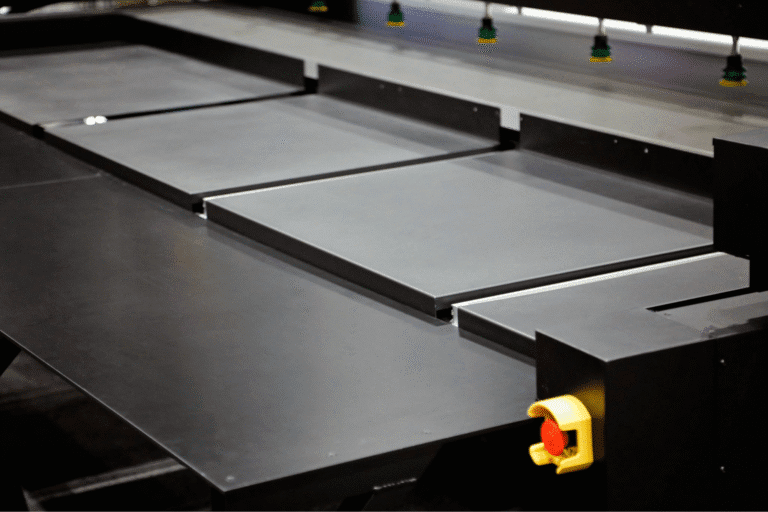

• Seven-zone, user-selectable vacuum system ensures efficient hold-down, no unintended media movement, and easy transitions between jobs

• UV-LED curing increases uptime and productivity with instant on/off and less maintenance

• Print on substrates up to 10 cm (4”) thick to better serve clients

THE VANGUARD

EDITION COLEX SHARPCUT

• Increased acceleration & cutting speeds for greater productivity

• Automated finishing system allows for reduced costs and increased efficiency

• Universal triple tool head enables the operator to be prepared to finish different substrates • Vision registration system & camera to ensure an accurate cut on every job

• Energy efficient 6-zone vacuum system to securely hold down printed sheets for proper finishing

• Solid steel welded frame for robust construction and minimized vibration

• Precision balanced aluminum rollers to protect substrates throughout the cutting process Cutter complete turnkey solution will help automate print service providers’ workflows and reduce costs associated with the finishing process of large format goods.

THE VANGUARD

EDITION OFFLOADING SYSTEM

• Printed rigid substrates are stacked neatly in a media collector for post-print production

• Print-to-stack production offers enhanced efficiency to take full advantage of print speed

• Automated stacking reduces the risk of substrate damage or dirtying

• Designed to handle 4’ x 8’ (121 cm x 243 cm) or 5’ x 10’ (152 cm x 304 cm) boards

• Configuration layout allows for quick, one-off jobs to be produced

• Printed stack is easily removed to allow for continuous production

• Capable of handling one- or two-sided print workflows